Garage & Concrete floor finishes

Backed by our Gold Standard transferabe Lifetime Warranty

The application of a garage floor coating system is not rocket science. It does however, take a certain level of expertise, especially in the concrete surface preperation.

While slow drying epoxy coating technoogy has been around for a very long time, the polyaspartic technology has revolutionized the industry, while allowing for one day installations. It is more durable than epoxy floor coat systems and given its chemical makeup, unike an epoxy system, it will contract with the expansion of concrete. Because of this, it gives polyaspartic coatings a significant edge over the epoxy floor systems.

This product has a very quick cure time, which means that knowledge of its working instructions are crutial. The advantage to the drytime, combined with its superior performance, comes with great value and convenience to us the instaler and you the customer. This actually allows us to do an install on this application in a single day. That gives potential customers more flexability in scheduling these types of projects, and because it is a one day installation, it also is more affordable and budget friendly than ever before.

-

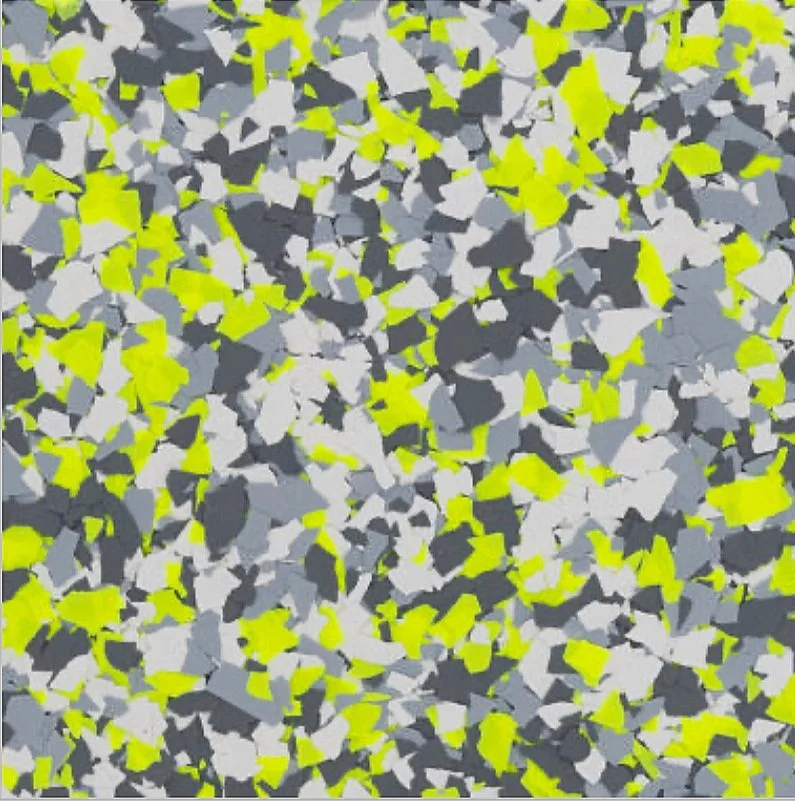

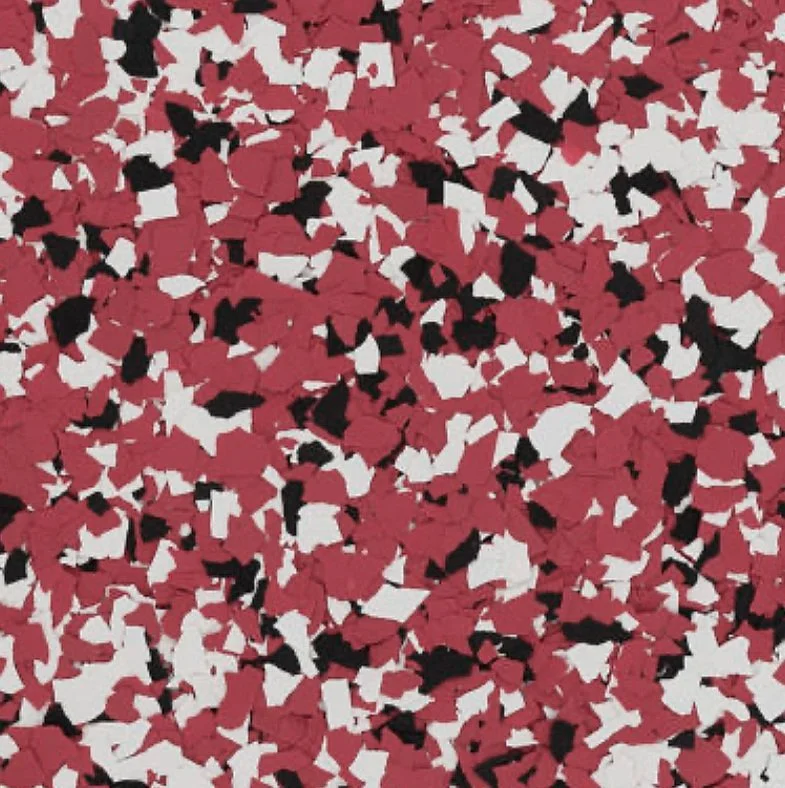

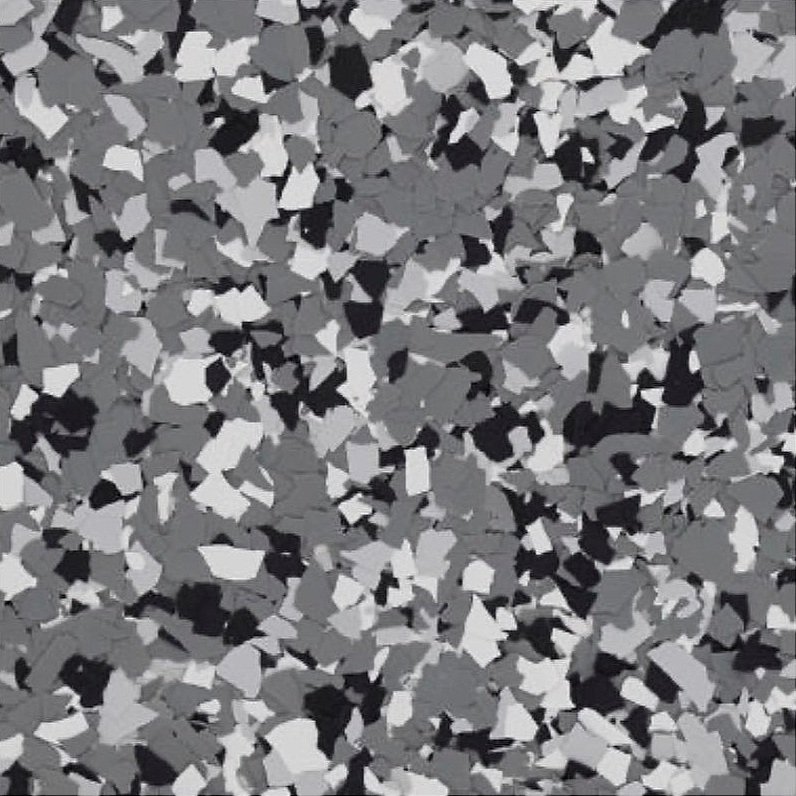

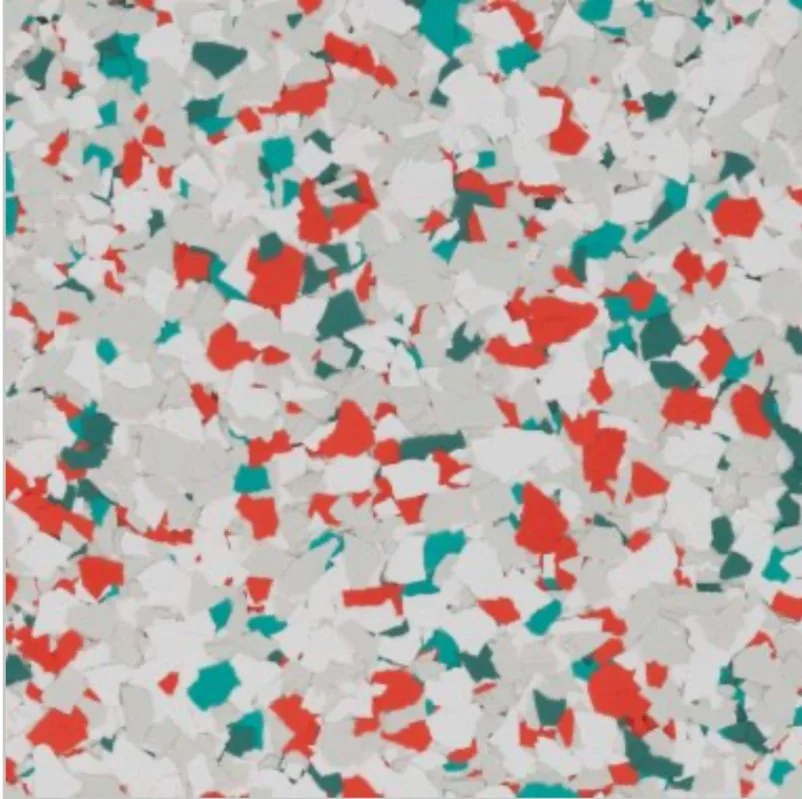

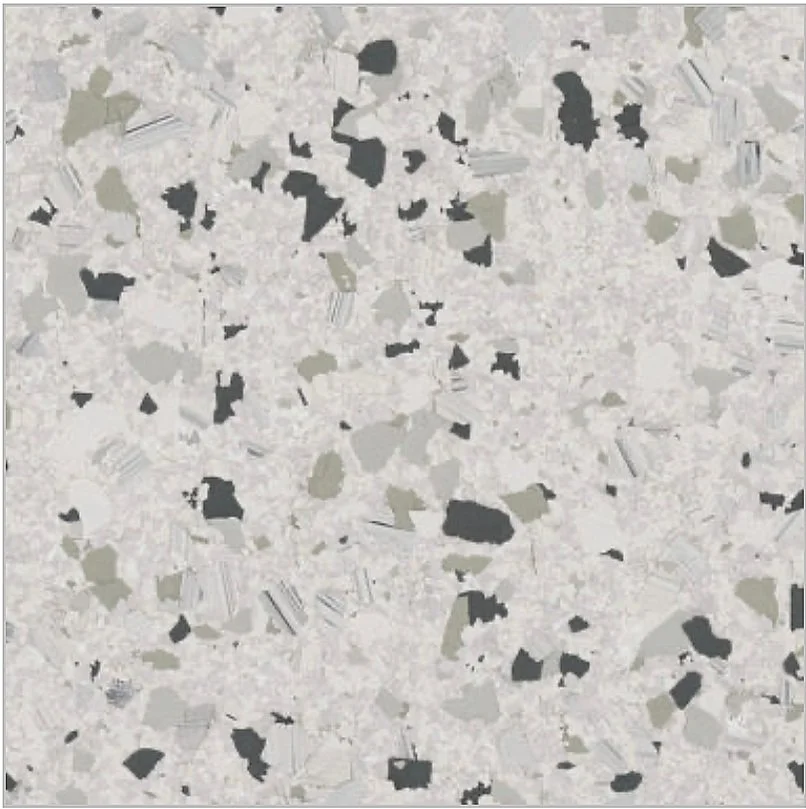

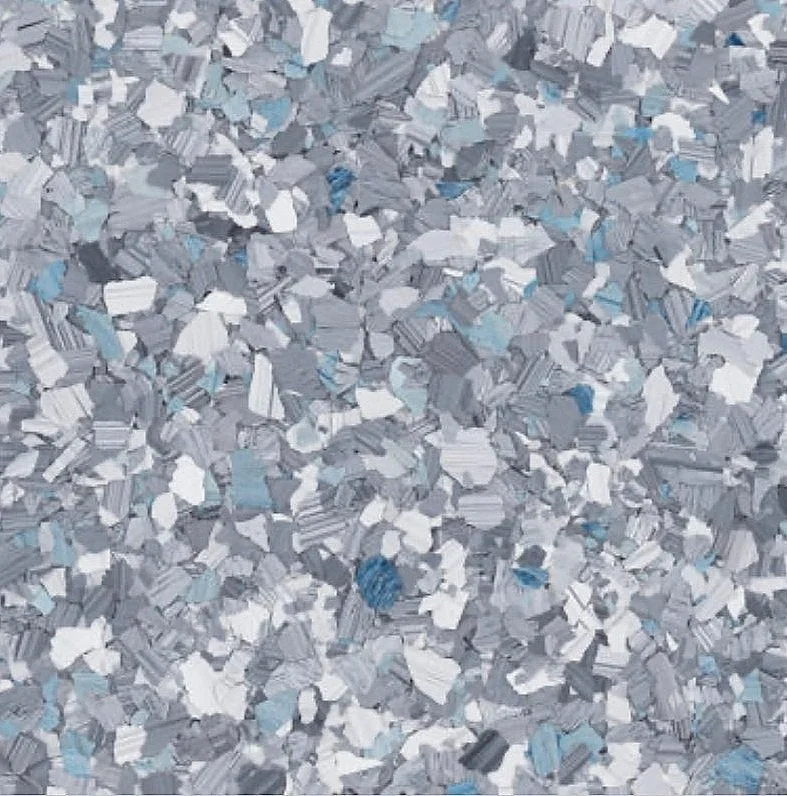

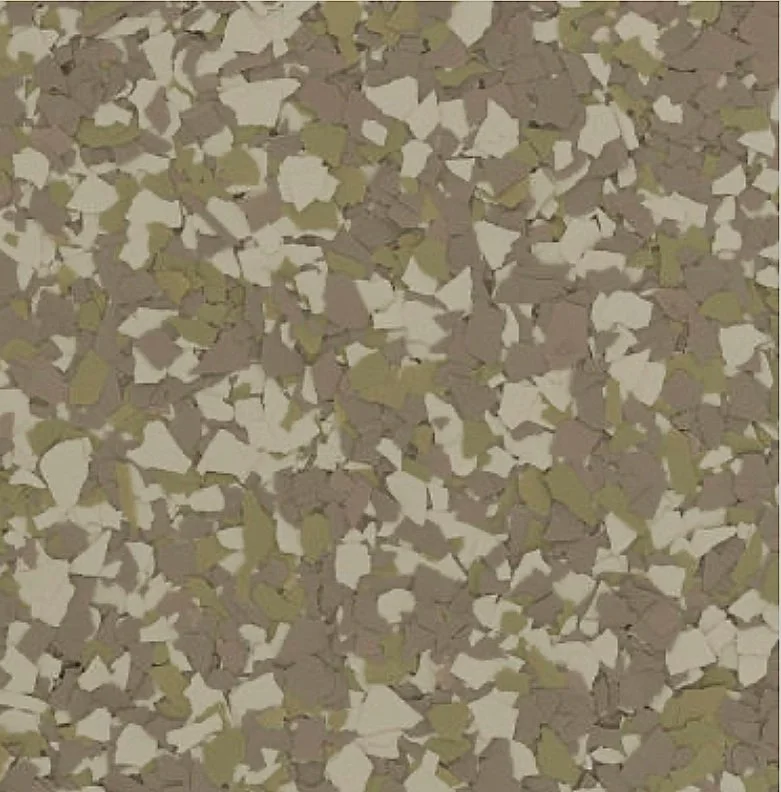

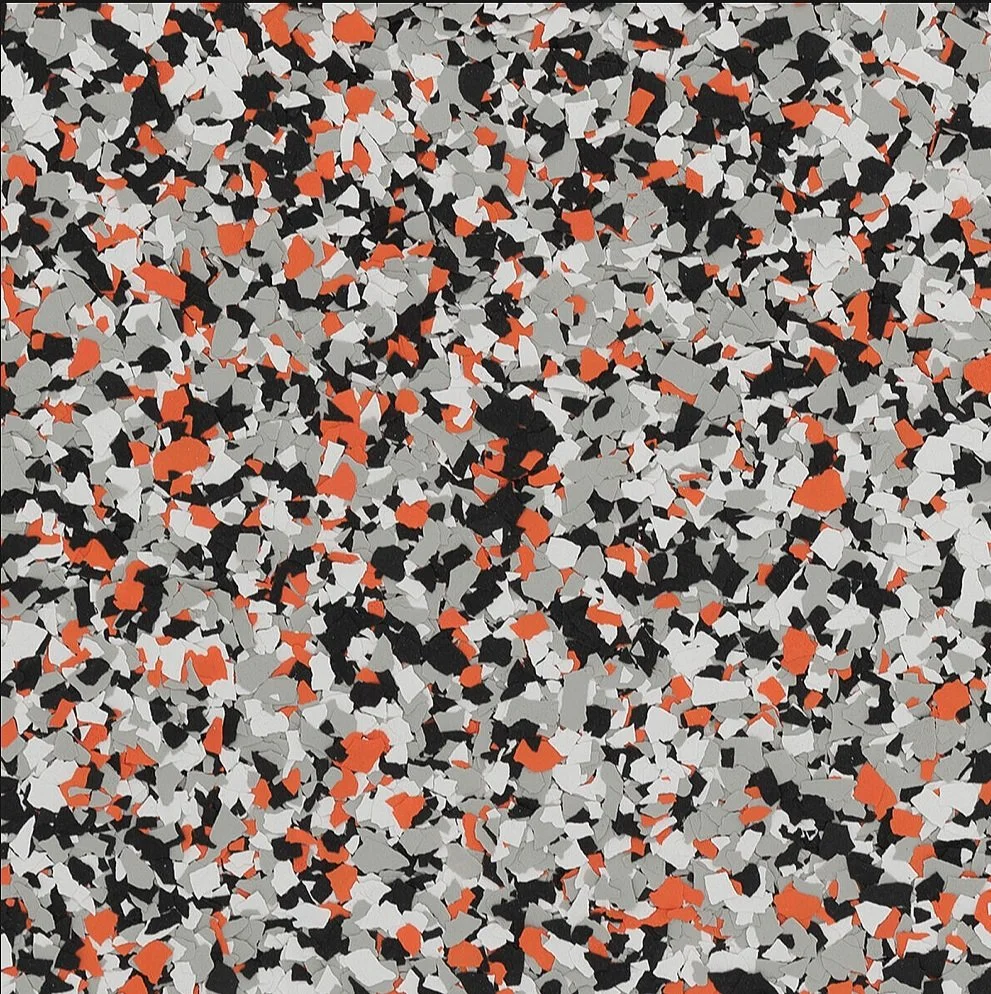

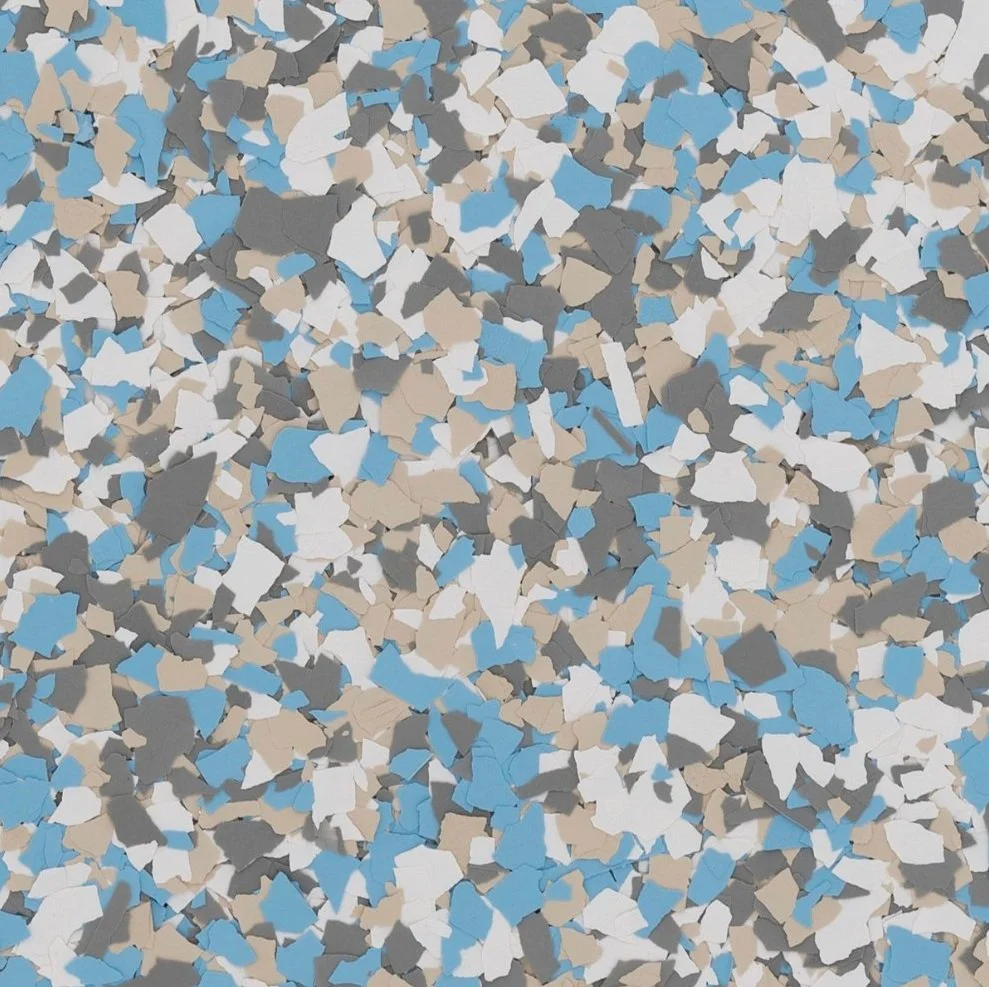

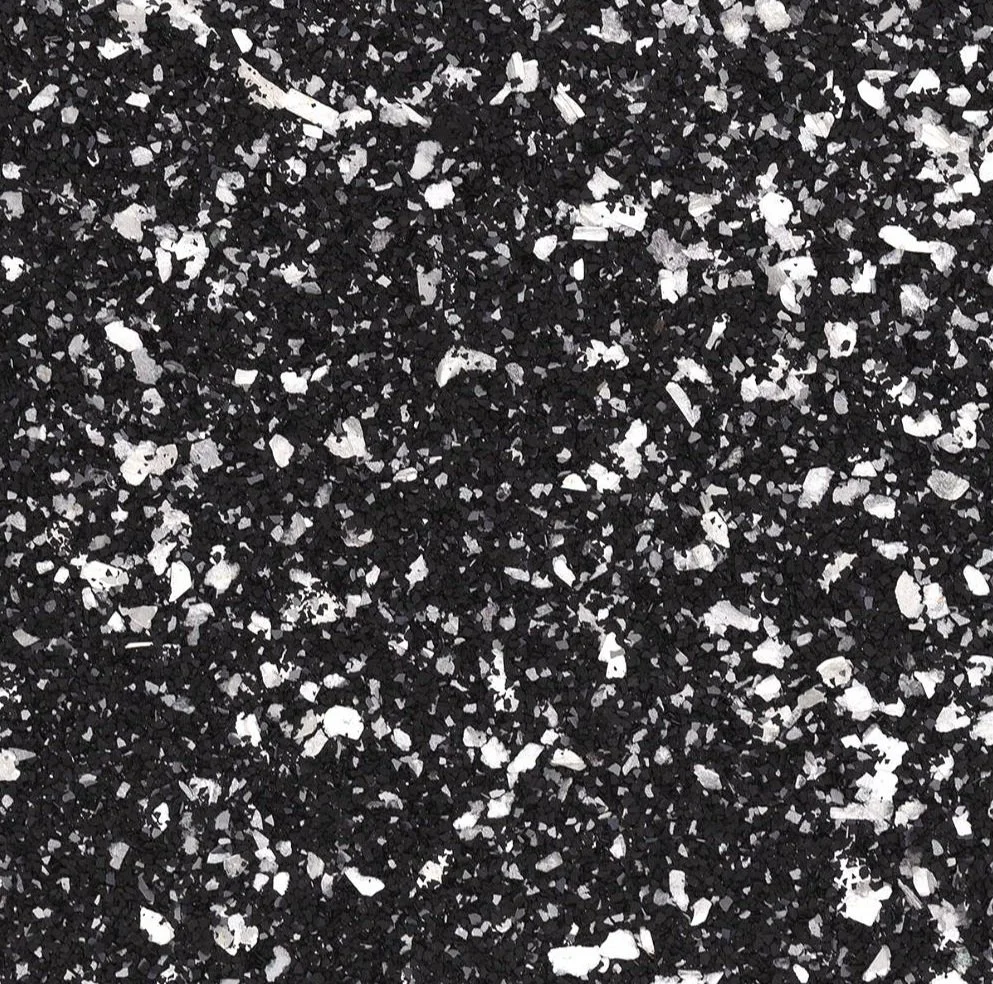

With hundreds of color combinations to choose from, rather its your team color or your she-shed, we can transform your garage floor using FLAKE chip color seections. Just because you do not see it below doesnt mean it doesnt exist. Just click on the link below to see more online samples.

-

It all starts here. Floor prep is the single most important step when selecting your contractor. Using a concrete grinder, we will remove any impurities that have polluted your concrete surface over its history of traffic. Once sealed, we will use a pollyurea sealant to fill the cracks that have formed through the setteling of your home. After the sealant self levels, we will grind the remainder flush to the rest of the surface. Your floor is now ready to begin to accept its bond.

-

A base coat of colored polyaspartic will next be applied using a squeege and back roller for a smooth and consistant finish. Flakes wil then be broadcast to rejection. once given a proper dry time, we will scrape and remove any loose and unaccepted flakes. At last we will apply a polyasparatic clearcoat as the final layer to your floor system. Clean up will be easy and floors will be left to dry for 24 hours. Total time will be between 6-8 hours for a two to three car garage.

-

It all begins with an idea. Maybe you want to launch a business. Maybe you want to turn a hobby into something more.

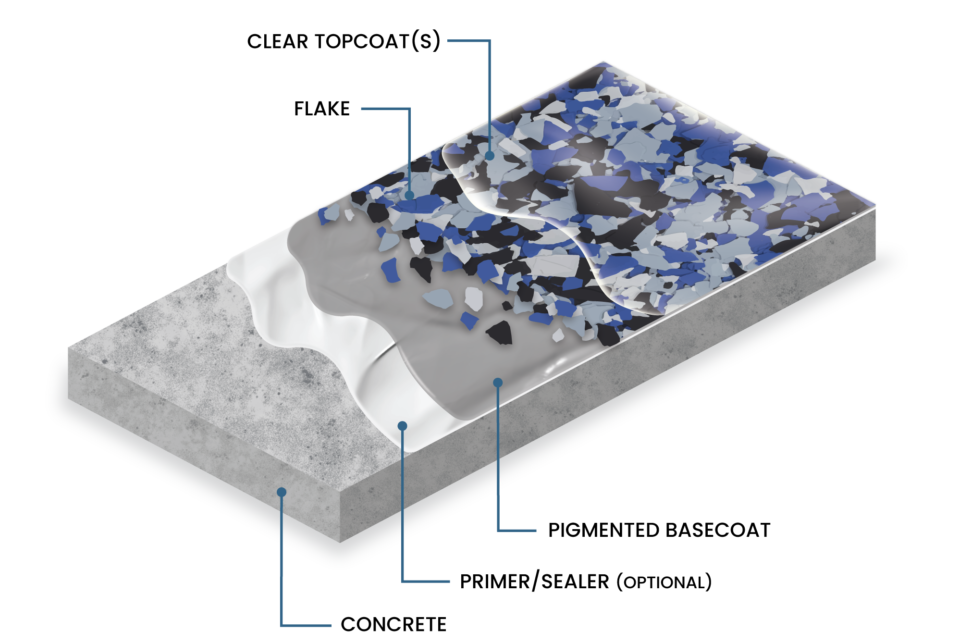

The above shows a generic layered coating system utilizing different options. Some systems out there require a primer coat. Products that use a primer coat are more likely to be a paint coating system and would be much weaker by nature. Epoxy like Polyaspartic coating systems, apply as a direct bond to the concrete. The next layer to the system is the FLAKE colored chips. There are a variety of different colors to choose from and those color samples can be viewed below. The final layer to this system is the clear Polyaspartic top coat that applies directly over the colored FLAKE chips. This gives the desired glossy and hardened finish coat needed to complete the Polyaspartic coating system. Unike the epoxy systems of the world, the Polyaspartic clear coat will not amber over time.